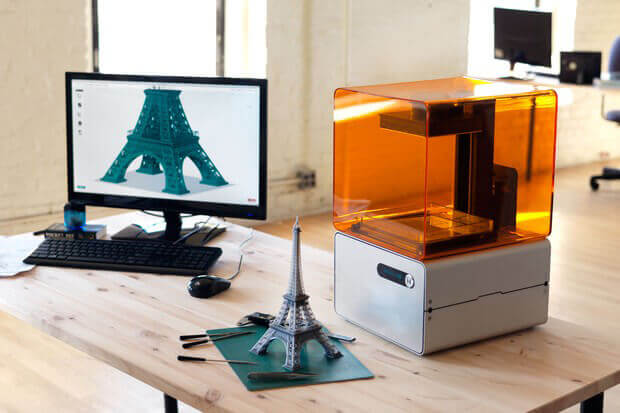

Just What is 3D Printing and How it is Changing Manufacturing as we Know it

Image from Engadget.com

3D printing is something you might have heard off but brushed off as unrealistic or too complicated or costly to worry about. But just what is 3D printing? It sounds like science fiction, but the truth is, it’s here to stay and it may be affecting your life sooner than you may have thought. The technology has been around for longer than many think and has a wide variety of uses and applications, and, at it’s core, is not a complicated as you may assume.

The very first 3D printer was actually created in 1984 but, like many new technologies, it was very expensive and had limited uses. Today, as the technology gets better and better, the prices of 3D printers have fallen and their uses have expanded into sectors as varied as biotechnology, architecture, aerospace, fashion, and eyewear!

Before we get into just what can be made using 3D printing, let’s talk about just what it is. 3D printing is also known by another name, additive manufacturing, and it makes good sense if you think of it like that. Many products are created using the more common method of subtractive manufacturing where material is taken away to create a product. Think of manufacturing a nut for instance. You may start with a cylinder of metal and then shave and cut away pieces of the metal until you are left with a nut. If you were to manufacture a nut using 3D printing, you would do the opposite. A 3D printer starts with nothing but a computer model of the product and then slowly builds up layers and layers of material until the final object is formed. Materials used by a 3D printer can include a variety of plastics, epoxy resins, steel and other metals, wax, and more.

One of the major advantages 3D printing has brought to the manufacturing world is the ability to engage in rapid prototyping. In the past creating a new, specialized prototype could take weeks or even months, so any changes made to the model just increased the time frame to the final product. 3D printing can, depending on the materials and complexity of the prototype, bring these times down significantly, sometimes producing an object in just hours or days. By shortening this timeframe many more changes, adjustments, and improvements can be worked into a new product thus creating a much better product in the final stage, without the long lead time one might expect. This process also allows for mass customization of products as well. Because there are no molds or specialized grinding or cutting tools needed to create a unique product, just a new computer model, it is significantly easier to customize individual products and still bring them to consumers as a reasonable cost.

While, at the moment, personal 3D printer usage is mostly limited to hobbyists and enthusiasts, there is a great potential for practical household usage as the technology improves even further and the costs continue to fall. As of now, home users have created items like an iPod case, watch bands, jewelry, and even chocolate art. Only time will tell what great new innovations will come out of 3D printing and it is likely only a matter of time before they become a regular fixture in many people’s homes.